Insulated Copper Tubes

Insulated Copper tubes are vital elements in the latest residential and industrial systems. These tubes combine the outstanding thermal conductivity and insulation properties of copper with modern insulation materials, which makes them essential in areas where the control of temperature and energy efficiency are crucial.

Industries like HVAC (heating ventilation, heating, as well as air conditioning) refrigeration, HVAC, and plumbing depend heavily on copper pipes that are insulated to keep the efficiency of their systems reduce energy consumption, and stop loss of heat. Their flexibility and dependability make them the preferred choice of engineers and technicians across the world. ZENGO GROUP Limited, a pioneer in this industry, offers the best products for your requirements. Discover premium solutions with Nexnice.

What Are Insulated Copper Tubes?

Insulated copper pipes are special conduits that are designed to move gases or fluids while limiting heat transfer. They are made up of a copper core, which is surrounded by insulation materials that offer thermal protection as well as preventing condensation.

Key Features:

- Thermal insulation: Efficaciously minimizes heat loss or gain while ensuring the temperature you want for the medium being transported.

- Corrosion resistance: Copper’s inherent resistance to corrosion makes it durable across a range of situations.

- Durability: they have been designed to endure extreme temperatures and mechanical strain without compromising performance.

Types of Insulation Materials

- Foam Insulation: lightweight Flexible, pliable, and easy to install. It is ideal for HVAC systems in homes.

- Rubber Insulation: Provides outstanding properties in terms of thermal and acoustic that are suitable for industrial use.

- Polyethylene (PE): material that is renowned for its resistance to moisture and durability, widely employed in plumbing systems.

- Fiberglass: Provides resistance to high temperatures for industrial applications that require specialized expertise.

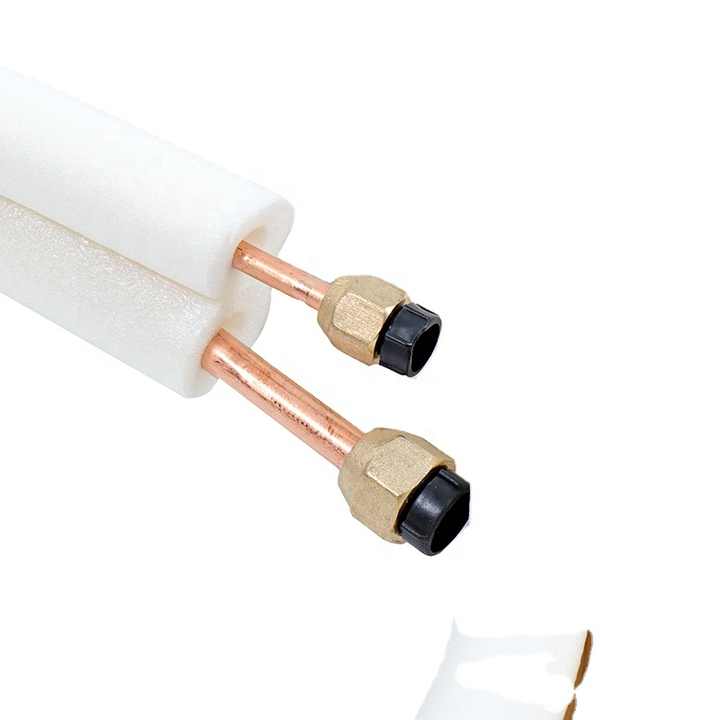

Comprehensive Product Details

Superior Insulation Options

Our Insulated copper tubes are equipped with two types of advanced insulation to meet a variety of requirements:

White PE Insulation: This type of insulation is specially intended for outdoor use and offers superior UV resistance. It protects copper tubes from harsh elements which ensures long-term performance and a minimal loss of energy. The white PE insulation is light and easy to put in and is a popular option for commercial and residential HVAC systems.

Black Rubber Insulation: Black rubber insulation offers enhanced thermal retention, and is perfect for areas that require superior heat conservation. It is extremely flexible which makes it ideal for installations that require a lot of effort. The rubber material provides durability against mechanical wear and tear, as well as enhancing the efficiency of heating systems.

The two insulation options are designed to cut down on energy consumption to avoid condensation and extend the lifespan of copper tubes, providing high performance for a variety of applications.

Technical Specifications

We provide a detailed breakdown of the product specifications to help you understand its capabilities:

| Attribute | Details |

| Copper Standard | ASTM B280 & C12200 |

| Insulation Thickness | 1″ for maximum thermal efficiency |

| Temperature Range | -40°C to 120°C |

| Compliance | Conforms to ASTM, UL 94, and SGS standards |

| Standard Length | 25 ft (Customizable lengths available) |

| Fittings | Pre-flared nuts for quick installation |

Applications of Insulated Copper Tubes

Insulated copper tubes are extensively utilized in a variety of industries because of their efficacy endurance, durability, and capacity to control temperature. ZENGO GROUP LIMITED provides tailored solutions to these needs.

- HVAC Systems: In HVAC systems Copper tubes that are insulated are vital for transporting refrigerants effectively. They can reduce energy losses as well as prevent condensation. They also assure smooth operation of the system which results in improved performance and lower operational expenses.

- Refrigeration: Insulated copper tubes assist in helping refrigeration systems keep their temperatures low by limiting heat loss. They help to improve energy efficiency and prolong the life of refrigeration units in residential and commercial environments by stopping heat fluctuations and condensation.

- Plumbing: In plumbing, insulated copper pipes increase efficiency and efficiency and energy efficiency by preventing heat loss from the hot water pipes. Copper’s resistance to corrosion ensures an extended life of service which makes them suitable for commercial and residential plumbing installations.

- Industrial Uses: Industries like pharmaceuticals, petrochemicals, and food processing make use of copper tubes that are insulated for use in applications like heat exchangers and chemical transportation. Their capability to withstand extreme pressures and temperatures is a must in these specific environments that ensure safety and efficiency.

Benefits of Using Insulated Copper Tubes

- Superior Thermal Performance: Insulated copper tubes ensure minimal heat transfer, making them highly energy-efficient. This is particularly valuable in HVAC and refrigeration systems where temperature consistency is critical.

- Long-Lasting Durability: Copper’s inherent properties, combined with protective insulation, provide exceptional resistance to wear and environmental factors, extending the product’s lifespan.

- Energy Efficiency: By reducing heat loss and condensation, these tubes significantly lower energy consumption, contributing to reduced operational costs.

- Ease of Installation and Maintenance: Their lightweight nature and flexibility simplify installation, while their durability minimizes maintenance needs.

How to Choose the Right Insulated Copper Tube?

Making the right choice of copper tube that is insulated is essential to ensure the effectiveness as well as the reliability of your equipment. ZENGO GROUP Limited provides experts to assist to make an educated decision that is compatible with your particular requirements and needs. Below are the most important aspects to take into consideration when choosing the most suitable copper tube for insulation:

Factors to Consider

1. Tube Diameter and Thickness

The wall thickness and diameter of the tube made from copper are important aspects in determining if it is suitable for the purpose it is intended. The diameter should be selected according to the flow rate to ensure that the tube can accommodate the amount of refrigerant or fluid that will be transported. A bigger diameter is required to accommodate higher flows and smaller diameters work well for systems that have low flow. The wall’s thickness should be chosen to meet the system’s pressure requirements as well as to give the necessary structural strength. When the tube is exposed to high pressure or high temperatures, walls that are thicker are required to ensure safety and effective operation.

2. Insulation Material and Thickness

Selecting the appropriate materials and insulation thicknesses is crucial for optimizing the thermal performance that the device. The insulation must be adapted to the operating temperature as well as the environmental conditions. For example, products like fiberglass or elastomeric foam have superior thermal resistance, and are frequently used in HVAC and refrigeration applications. In regions with extreme temperatures or conditions, a greater thickness of insulation could be needed to limit heat loss or gain which can improve energy efficiency. Insulation also prevents condensation, which can lead to an energy loss or corrosion It is therefore essential to select an insulation material with the right water resistance and a long-lasting durability.

3. Application-Specific Requirements

It’s crucial to ensure that the copper tube insulated can be used with particular refrigerant or liquid being carried. Different fluids may require specific coatings or materials to avoid chemical reactions or the degradation of the tube. For example, certain refrigerants have more corrosion than the others and require additional protection or special substances that can withstand corrosion. In addition, the tube should be in compliance with the relevant standards of industry for example, those developed in the ASHRAE in HVAC units, or that of the American Society for Testing and Materials (ASTM) for industrial and plumbing applications. Be aware of certifications from industry as well as environmental aspects (e.g. the exposure of UV radiation, humidity or other chemicals) is essential when choosing the best product.

Installation Tips and Best Practices

Proper installation of insulated copper tubes is crucial for achieving maximum efficiency and performance.

Step-by-Step Guide

- Planning: Determine the layout and measurements for the tubes.

- Cutting: Use specialized tools to cut the tube to the required length without damaging the insulation.

- Insulation Application: Ensure the insulation fits snugly over the copper tube, with no gaps.

- Sealing Joints: Use high-quality adhesive or tape to seal joints and prevent air infiltration.

Common Mistakes to Avoid

- Using incorrect tube sizes or insulation thickness.

- Leaving gaps or poorly sealed joints.

- Exposing the tubes to environments beyond their rated capacity.

Comparison: Insulated Copper Tubes vs. Alternatives

Copper vs. Aluminium

Copper has a more efficient thermal conductivity, resulting in quicker and more efficient heat transfer. This is why it is ideal for applications that require constant temperature control.

Aluminium is less heavy and more affordable than copper, but it is less durable and more susceptible to corrosion, particularly in humid conditions. In the long run copper tubes with insulation are much better due to their reliability and durability.

Insulated vs. Uninsulated Tubes

Insulated copper tubes reduce loss of heat and help prevent condensation, ensuring a consistent system efficiency and lower energy bills. Tubes that are not insulated however are more prone to failures due to temperature variations and corrosion potential from condensation accumulation.

Insulated tubes can also improve security by preventing slip hazards when in open environments.

Copper vs. PEX (Cross-Linked Polyethylene)

Copper is a durable material that has unmatched quality of conductivity and durability. This makes it ideal for high temperature as well as high pressure systems. PEX is a cheaper and flexible option, which is commonly employed in plumbing systems for residential use. lower temperatures.

In contrast to PEX there is a natural immune to microbial and UV degradation. growth, making copper tubes with insulation a superior choice for industrial and outdoor use.

PEX could be easier to set up in certain situations However, its longevity isn’t as robust as the efficiency of copper..

Steel vs. Copper

Steel is more durable and is able to handle higher structural loads, but it is less efficient at transferring heat and is more susceptible to rust when not galvanized. Copper’s inherent resistance to corrosion and outstanding thermal qualities make it a preferred material for both fluid and thermal transport applications.

Maintenance and Longevity

Maintenance Tips

- Regularly inspect the insulation for signs of wear, such as cracks or gaps.

- Clean the tube surface to prevent the build-up of dirt and debris.

- Address any issues promptly to avoid long-term damage.

Troubleshooting Common Issues:

- Condensation: Check for gaps in insulation and reseal if necessary.

- Damaged Insulation: Replace damaged sections to maintain thermal efficiency.

- Corrosion: Regular inspections can help identify early signs of corrosion and ensure timely repair.

Environmental and Energy Efficiency Benefits

Insulated copper tubes contribute significantly to environmental sustainability and energy savings:

- Energy Conservation: By minimizing thermal losses, they reduce the overall energy demand.

- Sustainability: Copper is 100% recyclable, making it an eco-friendly choice.

- Green Building Practices: Their use aligns with modern standards for energy-efficient and sustainable construction.

Future Trends in Insulated Copper Tubes

Innovations in Insulation Materials

The future of copper tube insulation is largely influenced by developments in the field of insulation materials. One of the most significant innovations is the creation of new insulation materials that offer enhanced performance in terms of acoustic and thermal.

These materials can significantly increase energy efficiency and reduce the noise generated by refrigeration and HVAC. Another trend that is exciting is the advent of nanotechnology that promises to increase insulation efficiency by enhancing its thermal performance and reducing the size that the product. This will result in smaller, more energy efficient systems. There is also increasing emphasis on green and bio-based insulation materials since sustainability is a major issue across all industries. These advancements are pave the path for eco-friendly and more efficient copper tubes that are insulated.

Emerging Applications

The insulated copper tube is discovering new applications in a variety of industries due to technological advances and evolving market requirements. In the field of renewable energy they are being increasingly used to make solar thermal collectors geothermal heating systems along with wind energy component. They help to transfer energy efficiently and keep the system running at its best. Furthermore in the field of the field of smart building the tubes are connected to IoT devices for real-time monitoring of energy and optimizing making for greener, more sustainable buildings. Another significant application is the field of electric vehicles (EV) sector in which copper tubes insulated are utilized in cooling systems for batteries improving the efficiency of thermal management as well as extending battery longevity. As these applications develop the possibilities of copper tubes insulated with insulation will continue to expand.

Market Growth and Demand

The demand for copper tubes that are insulated is increasing rapidly due to the growing focus on efficiency in energy use and sustainability for the environment. Consumers and businesses alike are focusing on energy efficient solutions to reduce operating costs and lessen the environmental impact. Furthermore, the rapid development of cities as well as industrialization of emerging economies is leading to the widespread use of insulated copper tubes for refrigeration, HVAC or industrial processes. Regulations and incentives from governments that encourage green construction projects as well as energy efficient technologies play a major role in increasing the outlook for global markets. These are factors that have positioned copper pipes that are insulated as an essential component to achieve sustainable development and optimizing energy consumption across a range of sectors.

As these developments, new applications as well as market expansion continue to develop The development of the future for copper insulated tubes appears promising, with improved performance as well as efficiency and sustainability across a variety of industries.

Frequently Asked Questions (FAQs)

1. What are insulated copper tubes used for?

Insulated copper tubes are used in HVAC, refrigeration, plumbing, and industrial applications. They transport refrigerants or fluids while maintaining temperature control, minimizing heat transfer, and preventing condensation. In plumbing, they efficiently carry hot and cold water, and in industrial settings, they transport various fluids, ensuring both thermal efficiency and corrosion resistance.

2. How do they improve energy efficiency?

Insulated copper tubes reduce energy losses by minimizing heat transfer and preventing condensation. Copper’s excellent thermal conductivity ensures efficient heat transfer, while the insulation keeps the desired temperature stable, reducing strain on system components. This leads to lower energy consumption, better performance, and cost savings.

3. What is the lifespan of insulated copper tubes?

With proper installation and maintenance, insulated copper tubes can last for decades. Copper is naturally resistant to corrosion, and the insulation helps protect it from environmental factors. Their long lifespan makes them a reliable choice for applications requiring durability and thermal efficiency.

4. How do insulated copper tubes compare to other materials like steel?

Copper offers superior thermal conductivity and corrosion resistance compared to steel. While steel is stronger, it lacks copper’s heat efficiency and is more prone to corrosion, requiring more maintenance. Copper is the preferred material for systems where energy efficiency and durability are key, making it more cost-effective in the long run.

5. Are insulated copper tubes environmentally friendly?

Yes, copper is 100% recyclable, making insulated copper tubes an environmentally friendly option. The insulation materials can also be eco-friendly, depending on the type. By improving energy efficiency and reducing power consumption, they help lower carbon footprints, making them a sustainable choice in various industries.

Conclusion

Insulated copper pipes are a fundamental component of modern energy-efficient systems, offering unmatched performance, durability, and environmental advantages. For HVAC, refrigeration plumbing, industrial uses, the pipes provide a cost-effective and reliable solution to maintain the efficiency of your system and ensuring sustainability. Selecting the best quality insulated copper tubes and implementing best practices will ensure optimal quality and durability. Make sure you choose ZENGO GROUP LIMITED for reliable solutions. You can rely on Nexnice for top solutions.